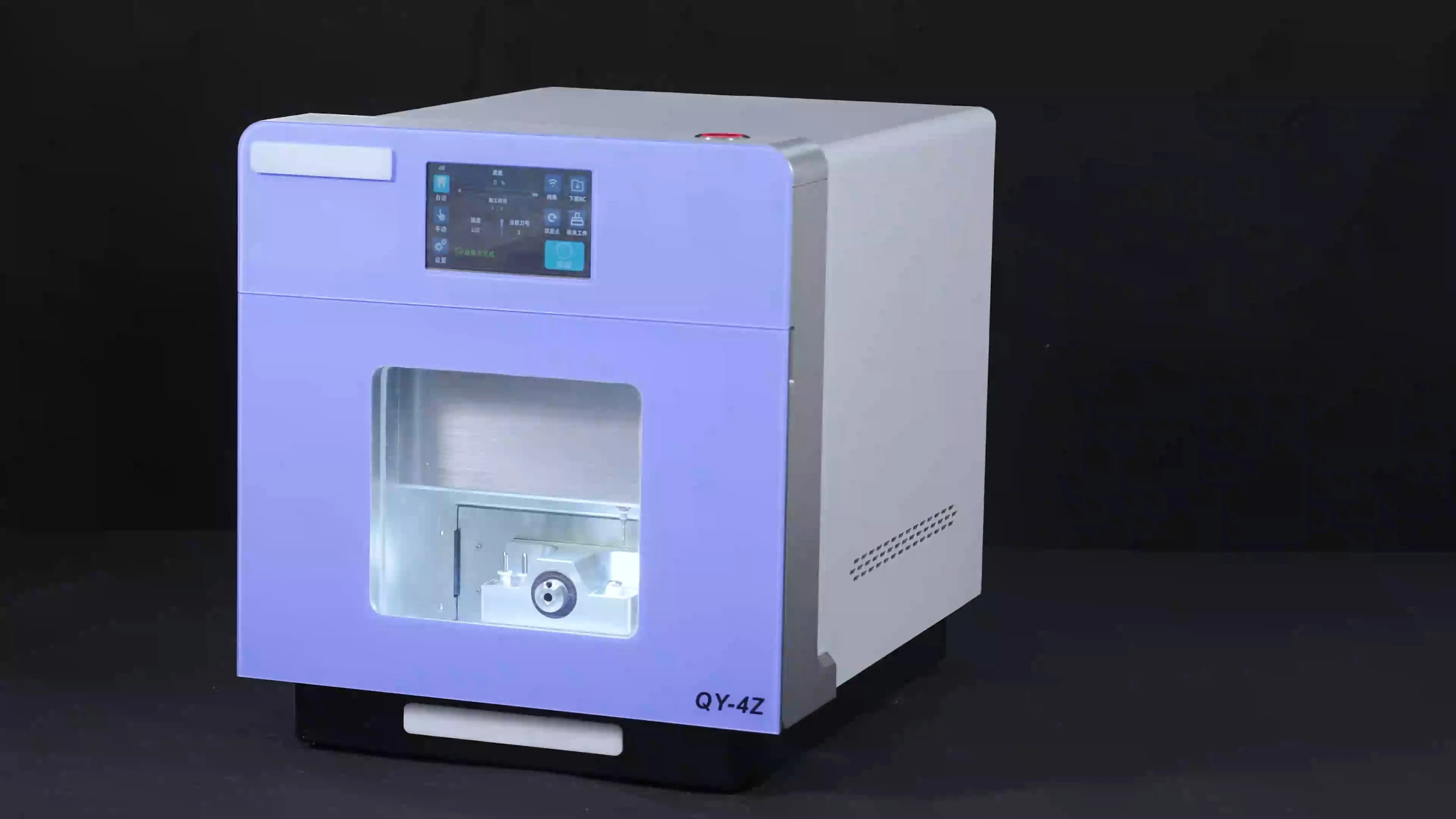

Table Dental Milling Machine for Dental cininc

Introduction

Equipped with easy-to-use and simplified one-button design, the QY-4Z lapping instrument covers a wide range of functions, such as loading and unloading blanks through one-button start, dismountable tool storage, wireless connection of multiple devices as well as automatic tool change function. What’s more, the device adopts a fully open system with background full-cycle upgrade system and French professional WORKNC DENTAL typesetting software, so that to efficiently produce restorations of outstanding surface quality and excellent accuracy of fit.

Details

● Small and compact in size.

● High steel resistance,which is not easily deformed.

● Dust-proof construction and polymeric materials are beneficial to long life expectancy.

● Easy and fast transfer via WiFi, cable or USB flash drive.

● Comprehensive detection and warning and alert function.

● Connection of multiple devices:1 PC can wirelessly connect to 10 QY devices at the same time for transmission cutting tasks, which can greatly help users expand business and enhance their productive capacities.

Parameters

|

Type of equipment |

Desktop |

|

Applicable materials |

Rectangular glass-ceramics;Li-based ceramics;Mixed materials;PMMA |

|

Type of processing |

Inlay and onlay; Veneer; Crown;Implant crown |

|

Working temperature |

20~40℃ |

|

Noise level |

~70dB(when working) |

|

X*Y*Z Stroke (in/mm) |

5 0×5 0×4 5 |

|

X.Y.Z.A semi-driven system |

Micro-step closed loop motors+Preloaded ball screw |

|

Repeat positioning accuracy |

0.02mm |

|

Wattage |

Whole machine ≤ 1.0 KW |

|

Power of spindle |

350W |

|

Speed of spindle |

10000~60000r/min |

|

Way of tool changing |

Electric automatic tool changer |

|

Way of material changing |

Electric push-button,no tools required |

|

Magazine capacity |

Three |

|

Tool |

Shank diameter ¢4.0mm |

|

Diameter of grinding head |

0.5/1.0/2.0 |

|

Supply voltage |

220V 50/60Hz |

|

Weight |

~40kg |

|

Size(mm) |

465×490×370 |

Applications