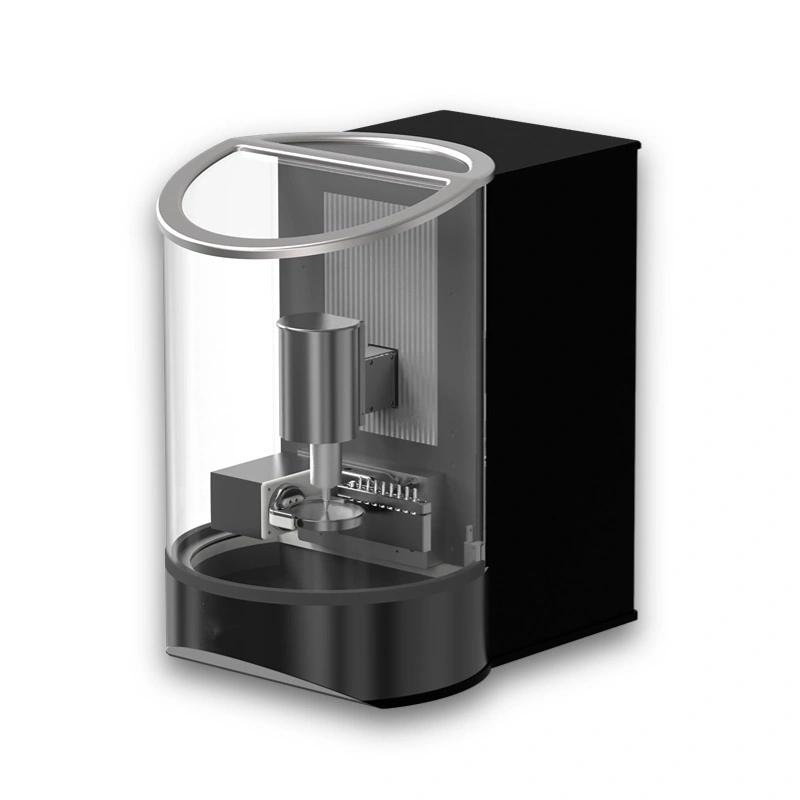

High accurate DN- D5Z Pro 5-Axis Zirconia Dental Milling Machine for Dental Clinic and Lab

Introduction

The C-type fixture makes the most of the material more efficiently, with a 360-degree + 80-degree large cutting angle, no need for grinding, and can handle all chamfers. Direct gear shaping is easier and more accurate.

True five-axis linkage, micron-level precision cutting, and continuous uninterrupted processing

The visible circular design is more fashionable and full of technology, making it a visible machining center.

Fully automatic intelligent control of 0~9 gears of dust collection, adaptable to needs. Automatic start and stop according to the cutting program, remote upgrade, and ultra-low maintenance.

Technologies

● 5-axis: The combined 5-axis is designed to achieve high-precision interpolation and high-speed response to maximize your productivity.

● Microstep closed-loop motors+Ball Screws: High accuracy and stability; highly-flexible

● Integrated high precision, high quality tool inspector: Equipped with the detection of tool length and tool breakage

● Gas source safety monitoring: The device stops operation when air pressure falls below 0.4MPa

● High-performance and high-precision closed-loop motors: Stable output; low noise level; long life expectancy

Parameters

|

Type of equipment |

Tabletop pneumatic 5-axis machine |

|

Applicable materials(Discs φ98) |

Zirconium oxide+PMMA+PEEK |

|

Efficiency |

9 to 16 minutes/pc |

|

X*Y*Z Stroke (in/mm) |

148x105x110 |

|

Angle (in degrees) |

A +30°/-145° |

|

Working temperature |

20~40℃ |

|

X.Y.Z.A.B drive systems |

Micro-step servo motors+Ball Screws |

|

Repeat positioning accuracy |

±0.02mm |

|

Wattage |

Whole machine ≤ 1.0 KW |

|

Power of spindle |

420W |

|

Speed of spindle |

10000~60000r/min |

|

Way of tool changing |

Pneumatic tool changer |

|

Magazine capacity |

Four, Five(option) |

|

Diameter of the knife handle |

¢4mm |

|

The size of knife |

R1.0 R0.5 R0.25 R0.15 |

|

Noise level |

~60dB(at work) |

|

~35dB(standby state) |

|

|

Supply voltage |

220V 50/60Hz |

|

Weight |

55Kg |

|

Size(mm) |

350*540*640 |

Features

● Flexible in use: The equipment is available as an affordable starter model, and can also be used to extend grinding systems of laboratories and cutting centers.

● Small in size and stylish in appearance.

● Stable all-aluminium frame construction.

● High efficiency: The cutting time of single zirconia can be controlled between 9 and 16 minutes.

● The GD-D5Z integrates high precision, high quality tool setter with 0.02mm repeat positioning accuracy

● The device is combined with high-performance touchscreens, together with tool setting, changing and alignment functions, which is easy to operate.

● With French Worknc typesetting software, the device stands out for high reliability, high efficiency, high precision and simple operation.

● The cutting tasks can be transferred via WiFi, network cable or USB memory sticks, which is convenient and time-saving.

● The rotation speed of the new high precision electric spindle can reach 60,000 rev/min with integrated pneumatic tool changing function.

● The simultaneous interpolation of the five-axis : X/Y/Z/A/B, provides larger swivel angle, so that more complex and delicate products can be processed.

● The removable tool magazine is specially designed for daily maintenance and tool replacement.

● The coloured LED signal lights serve to indicate machine errors and operating status.

● More efficient operation with modern design and user interface

Finished product demonstration

By use of our zirconia milling machine, the users can make the products whatever they need.